Industry 4.0

Opportunities and challenges of a networked industry

There is a broad spectrum of industrial companies. All of whom, from the small businesses to the global players, are facing a steady stream of changing customer requirements. There is a demand for tailored products to be delivered fast.

With the implementation of innovative campus solutions based on private LTE & 5G networks, BESCom is establishing a basis for the introduction of smart production and communication processes in companies.

Industry 4.0 is paving the way for entirely new approaches to be taken in industrial manufacturing.

Together with you, BESCom is establishing the groundwork to make this happen!

Opportunities and potential: Technological progress increasing sales

Industry networking provides your company with superb opportunities and potential for growth. The technological progress being made by the Internet of Things (IoT) is making this possible. According to a study carried out by pwc Deutschland German companies can expect a growth in sales of up to 2.5 percent per annum thanks to digitalisation.

All companies have one thing in common, however: the full effect of Industry 4.0 applications will not be felt without secure and comprehensive in-house communication.

What challenges do companies face?

Many companies are historically tied to their current locations, having established their presence over the years. The production buildings are generally concrete constructions that make it difficult to establish any comprehensive communication network on the premises. As networking increases, however, many companies are now dealing with a multitude of disruptive factors to their in-house communication.

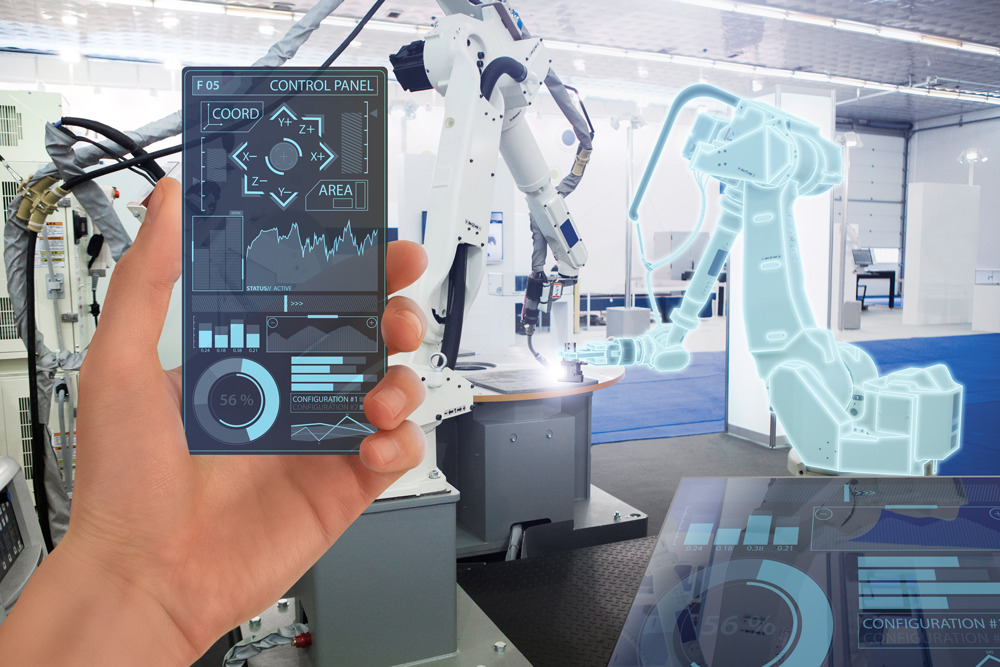

M2M communication for the management of operational processes

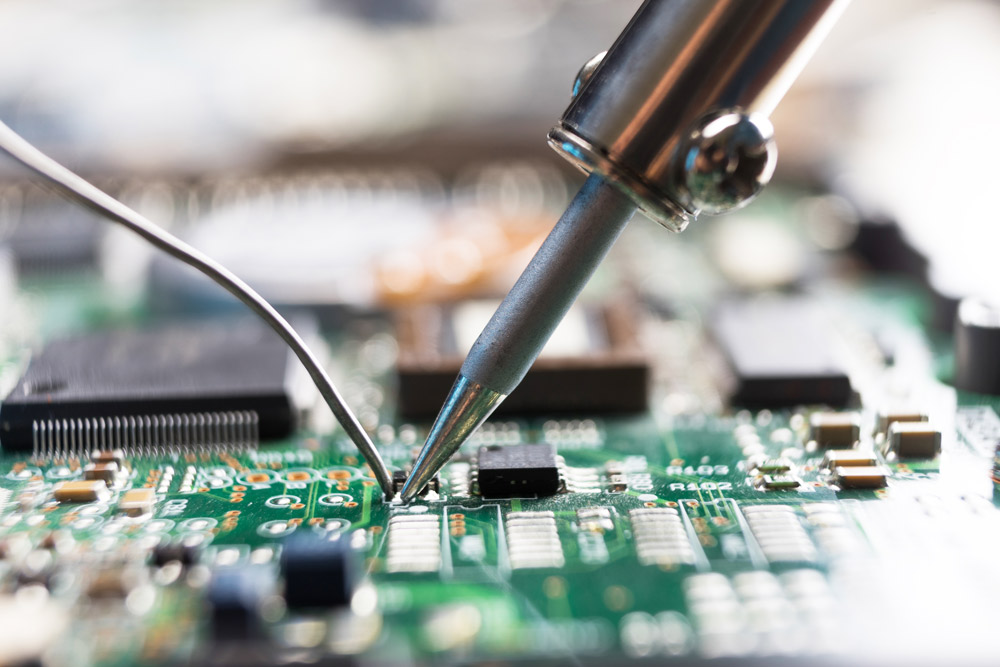

Many companies are now faced with the question of how their current operational processes can be adapted to the opportunities presented by an Industry 4.0 production environment. Communication from machine to machine (M2M) already facilitates the intelligent control of production processes. The introduction of M2M communication processes enables the generation of live data from production. The predictive maintenance of machines and the demand-oriented control of processes can be implemented as required.

The use of intelligent machinery also increases the number of monitoring tasks. Systems need to communicate with each other perfectly and be controlled centrally. A demanding task, however one which has the potential to improve processes.

Added value for you: Made possible by Industry 4.0

- Reduced downtimes and lower maintenance costs thanks to “predictive maintenance”

- Real-time monitoring and management of systems

- Cost savings thanks to optimised system control

BESCom is your partner for introducing a modern communication infrastructure: a requirement of Industry 4.0

Industry 4.0

Unreliable data transmission via WLAN

Transmitting data via WLAN lacks coordination and, when compared to other transmission technologies, cannot be relied upon to perform sufficiently. WLAN networks are spatially restricted in their range and provide insufficient coverage for entire production facilities.

Campus networks –

The central nervous system of smart factories

The use of WLAN in intralogistics is often accompanied by problems with the self-propelled machinery or failures of the driverless vehicles that navigate the company premises independently. The connection is lost when switching between WLAN radio cells, causing the vehicles to immediately stop in their tracks. Employees are required to manually reconnect the vehicles and containers with the network. One way to overcome this challenge is to implement a private LTE & 5G solution, which involves setting up a private mobile radio network within the company.

With BESCom, it is possible to implement a private campus solution within the company, thus creating the necessary conditions for an automation of in-house goods traffic.

Industry 4.0: Solutions & services from BESCom

BESCom boasts the entire scope of services required for the installation of a modern in-house communication infrastructure. Together with you, we analyse needs and execute planning according to your requirements.

Our experienced employees are tasked with establishing the infrastructure directly at your premises. We also plan this work with the aim of avoiding any interruption to operations.

Transmission of measured values from modern sensor technology

Setting up a campus network based on private LTE & 5G facilitates the exchange of sensor data within the private network. This makes it possible to integrate IoT end devices, sensors and machinery into the private network and thus reliably exchange data on site. If a local data centre component is added to the private network, calculations can take place directly without any delay. Hybrid wireless solutions make it possible to connect safety-critical radio systems with public mobile radio without jeopardising security levels and data protection.

Lone worker protection: Personal alarm systems

If employees are working out of sight and earshot of colleagues, there must be special protective measures in place. This involves special protection in the form of a personal alarm system. In the event of an accident, the employee can either trigger the alarm themselves or an alerter system will do this for them. Thanks to modern real-time localisation within the company radio network, the system is quickly able to find the injured employee. The alarm signal is sent to the control station and rescue measures can be initiated immediately. No valuable time is wasted!

Safe working environment with guard protection

Security personnel regularly patrol the grounds, following a fixed routine that includes all check points and observes specific check times. With a guard protection system, any faults that become apparent during the inspection round are reported automatically and any missing check point confirmations immediately trigger an alarm. There is no time wasted when it comes to organising an internal or external response. BESCom supports you during the installation of a new guard protection system.